Products

Device Data Collection Platform

Device Data Collection Platform

Device Remote Management Platform

Device Remote Management Platform

Industrial Data Visualization Platfom

Industrial Data Visualization Platfom

Monitoring And Energy-saving Platform

Monitoring And Energy-saving Platform

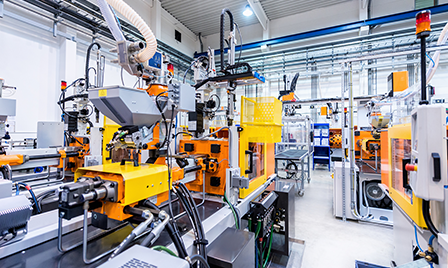

Industrial Digital Solutions

Industrial Digital Solutions

Industrial Intelligent Hardware

Industrial Intelligent Hardware

IoT data center

The SZn device data collection platform is connected to various industrial equipment (PLC, instruments, sensors, CNC machine tools, robots, etc.) to achieve data collection and bidirectional control of various industrial data on site; At the same time, the data will be stored on the platform after standardized processing to provide open data services and interfaces for various Industrial internet of things platforms, industrial Internet platforms and industrial software.

Fine control and efficient operation and maintenance

SZN equipment operation and maintenance management platform helps enterprises achieve remote management and maintenance of equipment in all regions of the world, and achieve preventive and Predictive maintenance through alarm notification and prediction model of Big data platform.

Data management cockpit

SZN industrial Data and information visualization platform is a lean management platform with functions such as equipment data management, equipment data display, 2D/3D configuration operation interface, customized large screen BI board, rich data reports and analysis models, and remote monitoring of equipment, which helps enterprises realize visualization and digital management.

Low carbon, environmental protection, green and energy-saving

Based on the decentralized nature of the energy system and the centralized nature of energy management requirements, this system integrates functions such as equipment supervision, energy consumption monitoring, energy efficiency analysis, and energy control based on the collection and analysis of various energy data such as water, electricity, heat, and gas.

Help enterprises to upgrade digitally

SZN provides overall solutions for smart factories, equipment manufacturers, environmental protection, energy, electric power and other industries, and has the overall project delivery capabilities from acquisition hardware, data platform, design integration, and implementation services.

Device networking, data collection, protocol analysis, edge computing

SZN Industrial Intelligent Hardware helps enterprises achieve rapid cloud access, remote management, and maintenance of equipment, assisting in digital upgrading and improving enterprise efficiency.

About Us

- Company Profile

- NEWS

- Cooperation

- Contact Us

Login Platform

设备数据采集平台

设备数据采集平台

设备远程运营管理平台

设备远程运营管理平台

云组态监控平台

云组态监控平台

能源监测及节能平台

能源监测及节能平台